Core Drilling Equipment: A guide to maximizing performance

Wiki Article

Comprehending the Importance of Core Exploration Devices in Modern Building Projects

Core drilling devices is important in contemporary building and construction, helping with specific openings for different systems. This tools consists of advanced tools like ruby and carbide-tipped drills, which enable for efficient sampling and installation. Spending in premium devices not just improves productivity but additionally enhances security on-site. However, understanding the full ramifications of these devices exceeds plain functionality. The details of their applications and future trends necessitate further exploration.

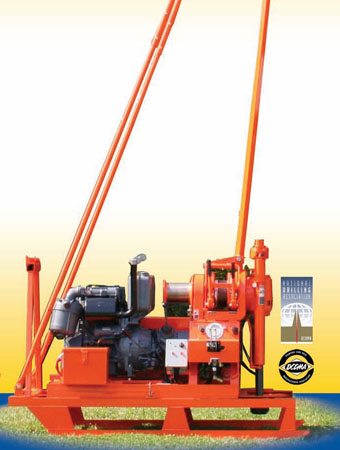

Kinds Of Core Drilling Equipment

When exploring the numerous kinds of core boring devices, it becomes obvious that each tool is developed for particular applications and materials. Core drills come in a number of forms, consisting of diamond core drills, which are suitable for difficult products like concrete and stone because of their precision and sturdiness. One more type is the carbide-tipped core drill, matched for softer substrates such as asphalt and brick. Furthermore, the rotary drill is usually used for basic functions, giving versatility throughout various jobs.Portable core exploration equipments, favored for their movement, enable on-site procedures in restricted areas. Conversely, bigger, stationary rigs are made use of for extensive drilling jobs, often in commercial settings. Each tool is complemented by numerous drill bits, customized to the firmness and composition of the product being permeated - Core Drilling Equipment. Understanding these distinctions is necessary for selecting the ideal equipment for efficient core drilling in building and construction jobs

Applications of Core Boring in Building

Core exploration plays an important function in different building and construction applications, as it permits for exact and efficient product removal in an array of projects. Among the primary applications is in the setup of plumbing and electrical systems, where exact holes are required for channels and pipelines to pass via walls and floors. Furthermore, core exploration is made use of for sampling objectives, enabling engineers to extract cylindrical examples of concrete or soil for testing and evaluation.An additional substantial use core drilling remains in the development of anchor factors, which are necessary for securing architectural components such as beam of lights and columns. It is additionally employed in refurbishing existing frameworks, enabling alterations without compromising the stability of surrounding materials. Core boring assists in the setup of A/c systems by offering openings for ductwork. Overall, these applications show core drilling's critical payment to contemporary building effectiveness and accuracy.

Benefits of Investing in High Quality Equipment

Purchasing quality devices is crucial for making certain ideal performance and resilience in building and construction jobs. High-grade core exploration tools uses remarkable accuracy, allowing specialists to attain accurate results while minimizing material waste. These tools are designed to sustain strenuous use, causing reduced maintenance prices and longer life-spans. Dependable tools can considerably enhance productivity, permitting teams to finish tasks a lot more efficiently and satisfy job target dates.One more benefit is that quality tools usually feature improved safety features, supplying drivers with far better control and minimizing the risk of accidents. Additionally, investing in reliable brands can lead to better customer support and guarantee solutions, ensuring that any type of concerns can be settled swiftly. Ultimately, the in advance financial investment in top quality devices settles in the lengthy run, causing enhanced overall job performance, lowered downtime, and greater customer fulfillment through premium workmanship.

Safety Considerations When Utilizing Core Boring Equipment

Guaranteeing safety while using core drilling tools is extremely important to protecting against mishaps and injuries on building websites. Operators has to use proper personal safety equipment (PPE), consisting of helmets, gloves, and eye defense, to minimize dangers related to flying particles and devices malfunctions. Proper training is essential, as it furnishes workers with the understanding to handle tools safely, recognize possible risks, and execute emergency treatments.

Regular maintenance and examination of core drilling tools can assist identify wear and tear, decreasing the likelihood of tools failing during procedure. In addition, preserving a well organized and tidy workplace reduces stumbling dangers and warranties that employees can operate equipment safely. Communication among staff member is essential, as it fosters a culture of safety and security where everyone knows their environments and prospective threats. By prioritizing these security factors to consider, construction tasks can operate much more successfully while protecting the health of all personnel involved.

Future Patterns in Core Drilling Modern Technology

Advancements in core exploration technology are poised to change the building sector, structure on the safety and security steps already highlighted in present techniques. Arising trends consist of the assimilation of robotics and automation, which aim to enhance accuracy and performance while lowering human error. Furthermore, the advancement of light-weight, mobile tools is making core exploration more easily accessible, enabling much easier transportation and arrangement on varied task sites.Developments in ruby drill little bit modern technology are resulting in longer-lasting devices that can cut through look what i found various products with minimized downtime. The consolidation of information analytics and IoT technology is additionally expected to improve surveillance and maintenance, making sure optimal efficiency and reducing functional costs. In enhancement, sustainable methods are getting grip, with suppliers concentrating on environment-friendly products and energy-efficient equipment. Collectively, these trends represent a transformative change, guaranteeing to enhance efficiency while prioritizing security and environmental responsibility in core drilling operations.

Regularly Asked Concerns

Exactly how Do I Choose the Right Core Drilling Tools for My Job?

To select the best core drilling tools, one should analyze job requirements, figure out the product type, review the needed opening size, and think about the tools's power source and mobility to guarantee Get More Information peak efficiency and effectiveness.What Is the Average Life-span of Core Drilling Devices?

The typical lifespan of core boring tools commonly varies from five to 10 years, relying on usage intensity, upkeep methods, and material types. Appropriate care can significantly expand their operational longevity, improving total effectiveness.Can Core Drilling Devices Be Rented Rather Than Acquired?

Yes, core drilling devices can be rented rather of purchased. Several building and construction business go with rentals to stay clear of and lower prices maintenance duties, especially for temporary projects where purchasing would be unwise or unnecessary.What Upkeep Is Required for Core Exploration Machines?

Exactly How Does Core Exploration Influence Surrounding Structures During a Task?

Core boring can influence surrounding structures by triggering resonances and small changes in structure stability. Correct strategies and devices are vital to minimize these impacts, making sure safety and security and stability of surrounding buildings throughout building tasks.Core exploration equipment is important in contemporary building, assisting in accurate openings for numerous systems. When discovering the various types of core boring equipment, it comes to be noticeable that each tool is developed for certain applications and materials. Core drills come in several kinds, consisting of diamond core drills, which are excellent for tough materials like concrete and rock due to their precision and sturdiness. Ensuring safety while utilizing core boring devices is critical to preventing crashes and injuries pop over to this site on building and construction websites - Core Drilling Equipment. Regular maintenance and examination of core boring tools can assist recognize wear and tear, minimizing the possibility of equipment failure throughout procedure

Report this wiki page